Jiangsu Minnuo Group Co.,Ltd

[Jiangsu,China]

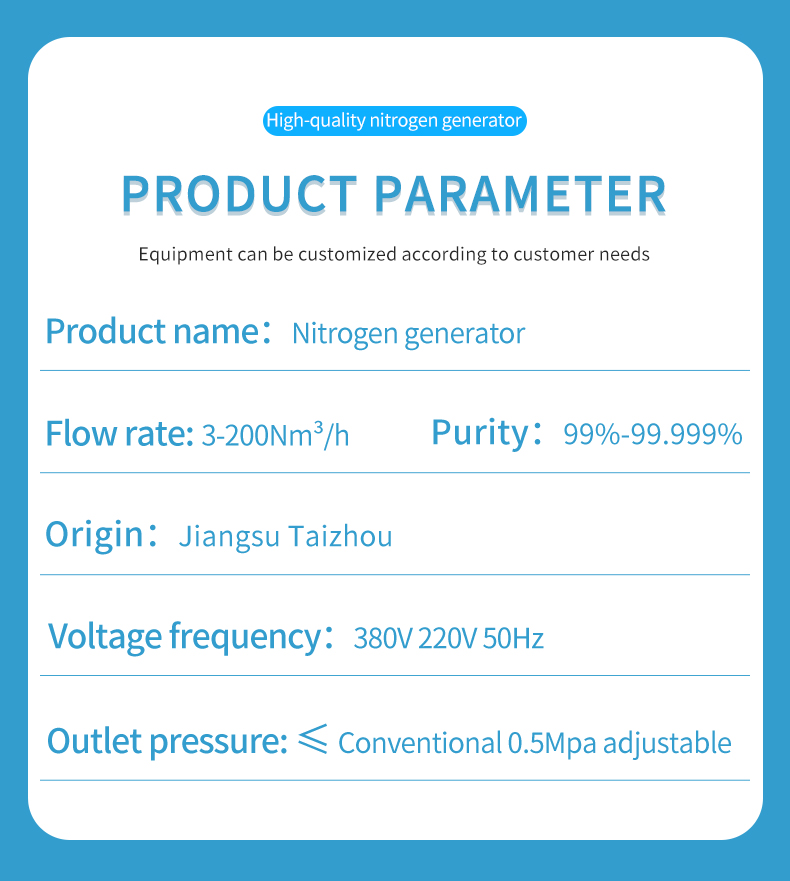

Business Type: Manufacturer , Trade Company Main Markets: Africa , Americas , Asia , Caribbean , East Europe , Europe , Middle East , North Europe , Oceania , Other Markets , West Europe , Worldwide Exporter: 91% - 100% Certs: GB, ISO13485, ISO9001, CCC, CE, Test Report, TUV, FDA Description: Nitrogen Generator For Powder Metallurgy,Energy Saving Nitrogen Generator,High Efficient Nitrogen Generator

- Home

- About Us

-

Products

-

Oxygen Generator >

- PSA Oxygen Generator

- Oxygen Generator For Hospital

- Medical Oxygen Generator

- Industrial Oxygen Generator

- Movable Oxygen Generator

- Oxygen Generator For Filling Cylinder

- High Purity Oxygen Generator

- VPSA Oxygen Generator

- 3-5Nm³/h Oxygen Generator

- 10-20Nm³/h Oxygen Generator

- 30-40Nm³/h Oxygen Generator

- 50-60Nm³/h Oxygen Generator

- 80-100Nm³/h Oxygen Generator

- 110-150Nm³/h Oxygen Generator

-

Nitrogen Generator >

- PSA Nitrogen Generator

- Nitrogen Generator For Laser Cutting

- Nitrogen Generator For Food Preservation

- Nitrogen Generator For Food Packaging

- Nitrogen Generator For Electronics

- Nitrogen Generator For Environmental Protection

- Nitrogen Generator For Heat Treatment

- Nitrogen Generator For Powder Metallurgy

- Nitrogen Generator For Chemical

- 99.9% Nitrogen Generator

- 99.99% Nitrogen Generator

- 99.999% Nitrogen Generator

-

Oxygen Generator >

- News

- Video

- Contact

- Send Inquiry